Secondary Screening

Secondary screening confirms “hits” identified by primary high-throughput screening assays, and goes a step further to measure their bioactivity; in a nutshell, secondary screening helps hits turn into therapeutic leads.

At this stage of the screening process, reliable and highly sensitive technology takes precedence over high-throughput setups, although researchers welcome ways to speed up the secondary screening process.

Functional tissue or cellular assays make up the majority of secondary screening assays; ELISAs that identify antibodies blocking receptor-ligand interactions are one example. Some problems may arise from user-to-user variability or from inconsistent washing and incubation times when performing manual ELISAs, and these inconsistencies can introduce errors in detection.

Another technique commonly used for secondary screening, flow cytometry measures an assortment of functional parameters. Sample preparation procedures for flow cytometry are cumbersome, involving multiple rounds of sample or reagent addition, washes, and centrifugation. Automation helps to overcome issues with ELISA and flow cytometry processes.

Shortfalls in reliable technologies to separate protein-ligand complexes, required for the secondary screening process, are another problem. Tedious and time-consuming linear rate-zonal density gradient separations are commonly used, which start with layering a discontinuous (step) gradient; however, these suffer from poor reproducibility, which is easily solved with automation.

Automation Removes Bottlenecks

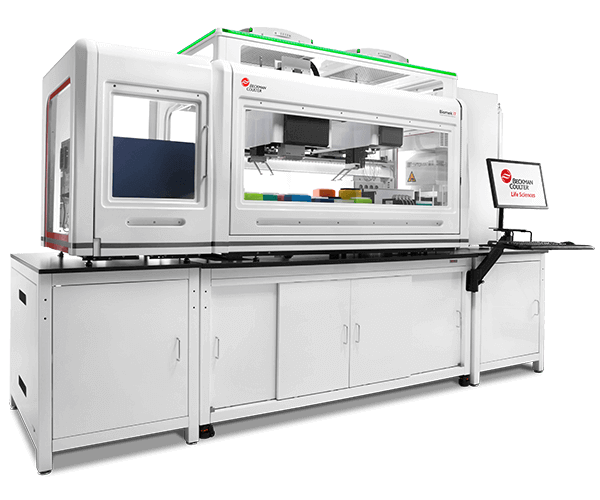

Biomek Workstations provide flexible automation solutions to accommodate various secondary screening workflows. Pipetting options include single to 96 channels, with customizable transfer steps such as tip touches or mixing. Configurable deck layouts, and the ability to integrate additional devices increase, the utility of these workstations.

The Biomek 4000 Workstation, for example, turns laborious procedures such as protein-ligand purification via layering discontinuous density gradients into simple, automated processes. The automated process allows researchers to walk away from the equipment during sample purification to perform other important laboratory tasks.

When Biomek Workstations are integrated with an EMax® Plus Microplate Reader from Molecular Devices LLC, for ELISA XTT assays—used to measure cell growth and viability in response to toxic compounds or other cellular treatments in the secondary screening process—the setup automates serial dilutions, cell plating, XTT reagent addition and plate reading.

Biomek Workstations also integrate with flow cytometers. Direct integration of a CytoFLEX Flow Cytometer with Biomek i-Series Automated Workstations enables complete automation of sample processing and data acquisition. Workstations permit selective tip pipetting for serial dilutions and processing of partial plates, and automation of every step from plating, to drug treatment, to cell staining.

Benefits of Secondary Screening Automation

As with any assay, data reliability depends on the accuracy and precision of sample preparation and analysis. Secondary-screening automation results in increased throughput and lab efficiency, plus reduced data inaccuracy, hands-on time, and turnaround time. Additional benefits include traceability of results, and the ability to integrate other devices for further downstream processing.

Summary:

- Secondary screening confirms which hits turn into leads.

- Functional cellular assays make up the majority of secondary screening assays.

- Automation of cellular assays and sample prep prevents errors and improves throughput.

- Biomek Workstations integrate and automate ELISAs, flow cytometry and other secondary screening processes.

Products for Secondary Screening

Biomek i7

(Hybrid) Minimize contamination with HEPA-filtered enclosure and sterile filtered tips

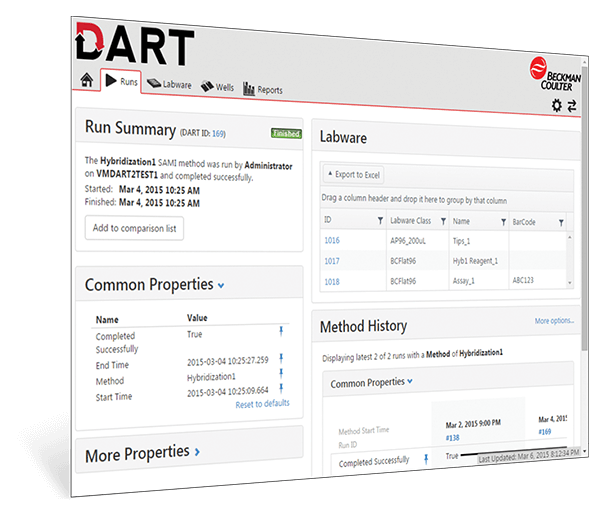

Biomek Software

Easy pipetting optimization for delicate cell models

DART Software

Ensure data integrity across integrated cellular analyzers