Cell Line Development – Selection and Enrichment

Summary

- Initial enrichment of protein-expressing cells enhances the efficiency of cell line development

- We automated the plating of CHO cells in semisolid media for colony growth and analysis

- Manual handling of the viscous media is highly inconsistent

- The ClonePix 2 identified and picked antibody secreting clones

- Cells are not exposed to harsh drug selection conditions

Cell line development is a highly involved and inefficient process. The quest to find cells that stably express and secrete antibodies or other protein products from a transfected pool of cells requires the screening of thousands of wells/cells. The efficiency of this process can be improved by enriching the post-transfection pool for those cells that have taken up the plasmid, such as through culturing the cells in a restrictive medium. However, a drawback to this approach is that the most desirable features – cell growth, protein production, and secretion – are not being assessed. In addition, even cells that have taken up the plasmids are highly stressed under selection conditions and this can adversely affect cell growth or production.

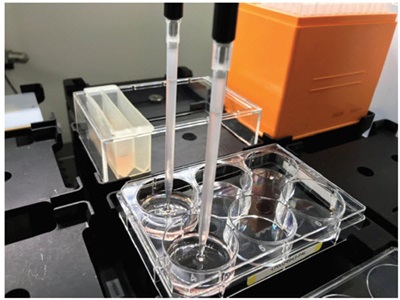

An alternative selection approach can be accomplished through the use of the ClonePix 2 System from Molecular Devices (Figure 1A). This system uses imaging to assay cell colonies formed in semi-solid medium for desirable attributes. Robust cell growth can be determined by colony size and addition of a fluorescent antibody-binding detection reagent to the medium identifies those clones with high levels of antibody secretion. The ClonePix 2 can then pick the preferred colonies from the medium and dispense them into 96-well plates for suspension culture and eventual single cell isolation and expansion.

One difficulty with this approach is consistent plating with the semi-solid medium. The viscosity of the medium makes it challenging to measure and plate consistently and the generation of bubbles can adversely impact the subsequent imaging or picking of colonies. To overcome these challenges, we utilized the Biomek i7 Workstation (Figure 1B) to automate plating of cells in the semi-solid medium.

Figure 1. ClonePix 2 (A) and Biomek i7 Workstation with integrated devices (B).

To prevent cultures from drying out, PBS was added between the wells of 6-well plates offline and plates were brought onto the Biomek system. Prior to plating, fluorescent CloneDetect reagent was added to the semi-solid CloneMedia CHO Growth A (both Molecular Devices) at 1:100. Knowing that a significant volume would be retained in a large pipette and dramatically reduce accuracy, we poured the medium to the fill line of a Beckman Coulter Quarter Reservoir Divided by Length (19 mL).

The automated method counted IgG-expressing CHO cells on an integrated Vi-CELL XR Cell Viability Analyzer and a moving dispense technique was used to transfer 19,000 cells throughout the reservoir to promote even distribution. Using fine pipetting control, cells were slowly mixed in the media and dispensed to 6-well plates without introducing bubbles (Figure 2). Plates were incubated in an integrated Cytomat incubator (Thermo Fisher) for 12 days to allow cells to form colonies and

secrete antibodies.

Figure 2. Semi-solid medium automation. The Span-8 pipettors of the Biomek i7 Workstation were used to add cells to medium, mix the cells in the reservoir, and dispense 3mL to 6-well plates.

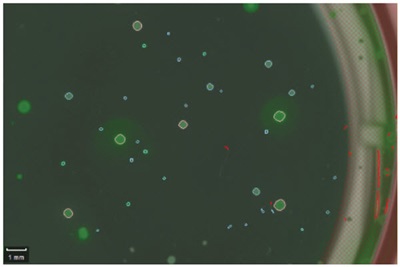

Figure 3 shows an overlay of brightfield and FITC images of one portion of a day 12 well. The presence of colonies indicates that cells were still viable after automated plating. The colonies are also spread throughout the well, indicating sufficient mixing prior to plating. This is essential as proximity to other clones can prohibit colony picking. Interestingly, despite using a stable expression line, the heterogeneity of the resulting clones illustrates the value of this selection approach. While most of the larger colonies are positive for fluorescent staining indicating IgG production, only a small portion show the large halo indicative of robust antibody secretion. This suggests that secretion can be a significantly limiting factor when only assaying protein concentration from cell media.

Figure 3. Colony imaging. Overlay of brightfield and fluorescent images of colonies 12 days after automated plating. Only a subset of the

colonies show the desired halo indicating antibody secretion.

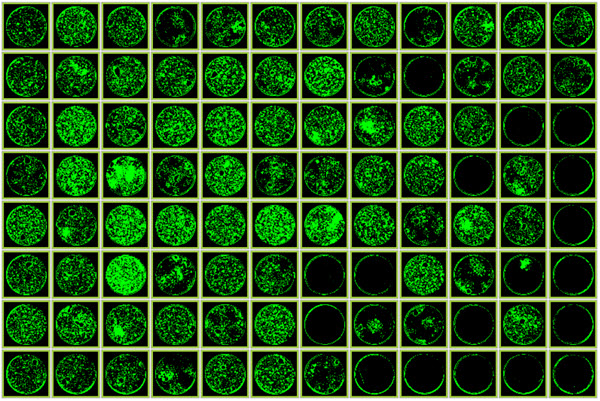

While the automated cultures were successfully imaged on the ClonePix 2, we sought to ensure these colonies were able to be picked. We identified 90 colonies to be picked from the 6-well plates based on colony size (largest to smallest). Figure 4 shows the confluence following two weeks of growth after picking. 79 of the 90 wells that should have received a clone showed cellular growth, with picking efficiency declining with colony size as expected. The 88% picking efficiency indicates excellent compatibility of the automated semisolid plating with the ClonePix 2.

Figure 4. Picking efficiency. 90 colonies were chosen for picking and 79 of the wells show cell growth after two weeks. Confluency was measured using a CloneSelect Imager (Molecular Devices).

By utilizing fluorescent imaging to score cell growth and protein secretion, the ClonePix 2 achieves better selection relevance than survival in restrictive medium. By automating the plating of cells in semisolid medium, one can relieve the inherent challenges of this reagent to achieve robust colony growth, imaging, and picking.

Biomek Automated Workstations are not intended or validated for use in the diagnosis of disease or other conditions. Beckman Coulter Life Sciences genomic reagent kits are for research use only.

Helpful Links

-

Reading Material

-

Application Notes

- 17-Marker, 18-Color Human Blood Phenotyping Made Easy with Flow Cytometry

- 21 CFR Part 11 Data Integrity for On-line WFI Instruments

- 8011+ Reporting Standards Feature and Synopsis

- Air Particle Monitoring ISO 21501-4 Impact

- Automated Cell Plating and Growth Assays

- Automated Cord Blood Cell Viability and Concentration Measurements Using the Vi‑CELL XR

- Automated Genomic Sample Prep RNAdvance

- Beer, Evaluation of Final Product and Filtration Efficiency

- Biomek Automated NGS Solutions Accelerate Genomic Research

- Biomek i-Series Automation of the Beckman Coulter GenFind V3 Blood and Serum DNA Isolation Kit

- Preparation and purification of carbon nanotubes using an ultracentrifuge and automatic dispensing apparatus, and analysis using an analytical centrifuge system

- Viability Assessment of Cell Cultures Using the CytoFLEX

- Classifying a Small Cleanroom using the MET ONE HHPC 6+

- Clean Cabinet Air Particle Evaluation

- Recommended cleaning procedure for the exterior surface of the MET ONE 3400+

- Counting Efficiency: MET ONE Air Particle Counters and Compliance to ISO-21501

- Critical Particle Size Distribution for Cement using Laser Diffraction

- CytoFLEX

- Detecting and counting bacteria with the CytoFLEX research flow cytometer: II-Characterization of a variety of gram-positive bacteria

- Efficient kit-free nucleic acid isolation uses a combination of precipitation and centrifugation separation methods

- Compensation Setup For High Content DURAClone Reagents

- Echo System-Enhanced SMART-Seq v2 for RNA Sequencing

- Grading of nanocellulose using a centrifuge

- Grading of pigment ink and measurement of particle diameter using ultracentrifugation / dynamic light scattering

- A Highly Consistent Bradford Assay on Biomek i-Series

- How to Use Violet Laser Side Scatter Detect Nanoparticle

- HRLD Recommended Volume Setting

- Long Life Lasers

- Particle Size Analysis Simple, Effective and Precise

- Flow Cytometric Analysis of auto-fluorescent cells found in the marine demosponge Clathria prolifera

- MET ONE Sensor Verification

- Metal colloid purification and concentration using ultracentrifugation

- Separation and purification of metal nanorods using density gradient centrifugation

- High-throughput Miniaturization of Cytochrome P450 Time-dependent Inhibition Screening Using the Echo 525 Liquid Handler

- Miniaturized and High-Throughput Metabolic Stability Assay Enabled by the Echo Liquid Handler

- Minimal Sample to Sample Carry Over with the HIAC 8011+

- Modern Trends in Non‐Viable Particle Monitoring during Aseptic Processing

- Particle diameter measurement of a nanoparticle composite - Using density gradient ultracentrifugation and dynamic light scattering

- Identification of Circulating Myeloid Cell Populations in NLRP3 Null Mice

- Optimizing the HIAC 8011+ Particle Counter for Analyzing Viscous Fluids

- Particle testing in cleanroom high-pressure gas lines to ISO 14644 made easy with the MET ONE 3400 gas calibrations

- Pharma Manufacturing Environmental Monitoring

- Pharma Manufacturing Paperless Monitoring

- Analysis of plant genome sizes using flow cytometry: a case study demonstrating dynamic range and measurement linearity

- Protein purification workflow

- Calibrating the QbD1200 TOC Analyzer

- Detection Limit

- JP SDBS Validation

- Using the Coulter Principle to Quantify Particles in an Electrolytic Solution for Copper Acid Plating

- USP 787 Small Volume Testing

- A fully automated plate-based optimization of fed-batch culture conditions for monoclonal antibody-producing CHO cell line

- A Deeper Look at Lipid Nanoparticles

- A High-Throughput, Automated Screening Platform for IgG Quantification During Drug Discovery and Development

- Automated Research Flow Cytometry Workflow Using DURA Innovations Dry Reagent Technology with the *Biomek i7 Automated Workstation and *CytoFLEX LX Flow Cytometer

- Automating antibody titration using a CytoFLEX LX analyzer Integrated with a Biomek i7 Multichannel workstation and Cytobank streamlined data analysis

- Automated IDT Alt-R CRISPR/Cas9 Ribonucleoprotein Lipofection Using the Biomek i7 Hybrid Automated Workstation

- Monitoring Plant Cell Cultures with BioLector and Multisizer 4e Instruments

- Monitoring Yeast Cultures with the BioLector and Multisizer 4e instruments

- Biomek i7 Hybrid Automated KAPA mRNA HyperPrep Workflow

- Comparative Analysis of DURAClone IM T-Cell Subsets Antibody Panel: Conventional vs. Spectral Flow Cytometry on CytoFLEX mosaic Spectral Detection Module

- Cultivation of suspended plant cells in the BioLector®

- Determination of cell death in the BioLector Microbioreactor

- Echo System-Enhanced SMART-Seq v4 for RNA Sequencing

- A Simple Guide to Selecting the Right Handheld Particle Counter for Monitoring Controlled Environments

- Linearity of the Vi-CELL BLU Cell Counter and Analyzer

- Miniaturized 16S rRNA Amplicon Sequencing with the Echo 525 Liquid Handler for Metagenomic and Microbiome Studies

- Nanoliter Scale High-Throughput Protein Crystallography Screening with the Echo Liquid Handler

- Preparation of Mouse Plasma Microsamples for LC-MS/MS Analysis Using the Echo Liquid Handler

- Robust and High-Throughput SARS-CoV-2 Viral RNA Detection, Research, and Sequencing Using RNAdvance Viral and the OT-2 Platform

- The Valita Aggregation Pure assay: A rapid and accurate alternative for aggregation quantification of purified monoclonal antibodies

- Accurate enumeration of phytoplankton using FCM

- Accurately measures fine bubble size and particle count

- Achieving Compliant Batch Release – Sterile Parenteral Quality Control

- Adaptive Laboratory Evolution of Pseudomonas putida in the RoboLector

- Adjustment of the pH control settings in the BioLector Pro microbioreactor

- Aerobic cultivation of high-oxygen-demanding microorganisms in the BioLector XT microbioreactor

- An Analytical Revolution: Introducing the Next Generation Optima AUC

- Anaerobic cultivation processes of probiotic bacteria in the BioLector XT microbioreactor

- Analyzing Mussel/Mollusk Propagation using the Multisizer 4e Coulter Counter

- Assay Assembly for Miniaturized Quantitative PCR in a 384-well Format Using the Echo Liquid Handler

- Automated 3D Cell Culture and Screening by Imaging and Flow Cytometry

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Automating a Linear Density Gradient for Purification of a Protein:Ligand Complex

- Automating Biopharma Quality Control to Reduce Costs and Improve Data Integrity

- Automating Bradford Assays

- Automating Cell-Based Processes

- Automating Cell Line Development

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Automation of CyQuant LDH Cytotoxicity Assay using Biomek i7 Hybrid Automated Workstation to Monitor Cell Health

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Automation of protein A ELISA Assays using Biomek i7 hybrid workstation

- Avanti J-15 Centrifuge Improves Sample Protection Maximizes Sample Recovery

- The New Avanti J-15 Centrifuge Time Saving Deceleration Profile Improves Workflow Efficiency

- Avanti JXN Protein Purification Workflow

- Avoid the Pitfalls When Automating Cell Viability Counting for Biopharmaceutical Quality Control

- Monitoring E. coli Cultures with the BioLector and Multisizer 4e Instruments

- Biomek Automated Genomic Sample Prep Accelerates Research

- Biomek i-Series Automated AmpliSeq for Illumina® Library Prep Kit

- Biomek i-Series Automated Beckman Coulter Agencourt RNAdvance Blood Kit

- Biomek i-Series Automated Beckman Coulter Agencourt RNAdvance Cell

- Biomek i-Series Automated Beckman Coulter Agencourt SPRIselect for DNA Size Selection

- Biomek i-Series Automated IDT® xGen Hybridization Capture of DNA libraries on Biomek i7 Hybrid Genomics Workstation

- Biomek i-Series Automated Illumina Nextera DNA Flex Library Prep Kit

- Biomek i-Series Automated Illumina® Nextera XT DNA Library Prep Kit

- Biomek i-Series Automated Illumina TruSeq DNA PCR-Free Library Prep Kit

- Biomek i-Series Automated Illumina TruSeq® Nano DNA Library Prep Kit

- Biomek i-Series Automated Illumina TruSeq® Stranded mRNA Sample Preparation Kit Protocol

- Biomek i-Series Automated Illumina TruSeq® Stranded Total RNA Sample Preparation Kit Protocol

- Biomek i–Series Automated Illumina® TruSight Tumor 170 32 Sample Method

- Biomek i-Series Automated KAPA HyperPrep and HyperPlus Workflows

- Biomek i-Series Automated New England Biolabs NEBNext® Ultra II DNA Library Prep Kit

- Biomek i-Series Automated SurePlex PCR and VeriSeq PGS Library Prep for Illumina

- Biomek i-Series Automation of the DNAdvance Genomic DNA Isolation Kit

- Cell Counting Performance of Vi–Cell BLU Cell Viability Analyzer

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Cell Line Development – Data Handling

- Cell Line Development – Limiting Dilution

- Cell Line Development – Selection and Enrichment

- Cellular Analysis using the Coulter Principle

- Changes to GMP Force Cleanroom Re-Classifications

- Characterizing Insulin as a Biopharmaceutical Using Analytical Ultracentrifugation

- Cleanroom Routine Environmental Monitoring – FDA Guidance on 21 CFR Part 11 Data Integrity

- Fda guidance 21 cfr compliance guide for met one 3400 plus

- Cluster Count Analysis and Sample Preparation Considerations for the Vi-CELL BLU Cell Viability Analyzer

- Comparing Data Quality & Optical Resolution of the Next Generation Optima AUC to the Proven ProteomeLab on a Model Protein System

- Conducting the ISO 14644-3 Cleanroom Recovery Test with the MET ONE 3400+

- Considerations of Cell Counting Analysis when using Different Types of Cells

- Consistent Cell Maintenance and Plating through Automation

- Control of Spheroid Size and Support for Productization

- Control Standards and Method Recommendations for the LS 13 320 XR

- Data-integrity-and-met-one-3400-plus-function-for-pharma

- Cultivation of Mammalian Cells in the Cydem VT System Bioreactor Module

- Cydem VT Automated Clone Screening System – Generating an Antibody Standard Curve

- Cydem VT System: A Comparison to Traditional Clone Screening Platforms

- Optimize Clone Screening: Time Savings with the Cydem VT System in Monoclonal Antibody-Producing Cell Line Development Workflows

- Use Machine Learning Algorithms to Explore the Potential of Your High Dimensional Flow Cytometry Data Example of a 20–color Panel on CytoFLEX LX

- How to use R to rewrite FCS files with different number of channels

- A new approach to nanoscale flow cytometry with the CytoFLEX nano analyzer

- CytoFLEX nano Flow Cytometer: the new frontier of nanoscale Flow Cytometry

- Detecting Moisture in Hydraulic Fluid, Oil and Fuels

- Detection of Coarse Particles in Silica Causing Cracks in Semiconductor Encapsulants

- Detection of foreign matter in plating solution using Multisizer4e

- Determination of drug-resistant bacteria using Coulter counters

- Determination of Size and Concentration of Particles in Oils

- DO-controlled fed-batch cultivation in the RoboLector®

- dsDNA Quantification with the Echo 525 Liquid Handler for Miniaturized Reaction Volumes, Reduced Sample Input, and Cost Savings

- Screening of yeast-based nutrients for E. coli-based recombinant protein production using the RoboLector Platform

- E. coli fed-batch cultivation using the BioLector® Pro

- Effective Miniaturization of Illumina Nextera XT Library Prep for Multiplexed Whole Genome Sequencing and Microbiome Applications

- Efficient clone screening with increased process control and integrated cell health and titer measurements with the Cydem VT Automated Clone Screening System

- Efficient Factorial Optimization of Transfection Conditions

- Enhancing Vaccine Development and Production

- Enumeration And Size Distribution Of Yeast Cells In The Brewing Industry

- European Pharmacopoeia EP 2.2.44 and Total Organic Carbon

- Evaluation of Instrument to Instrument Performance of the Vi-CELL BLU Cell Viability Analyzer

- Exosome-Depleted FBS Using Beckman Coulter Centrifugation: The cost-effective, Consistent choice

- Filling MicroClime Environmental Lids

- Flexible ELISA automation with the Biomek i5 Workstation

- Friction Reduction System High Performance

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Fully Automated Peptide Desalting for Liquid Chromatography–Tandem Mass Spectrometry Analysis Using Beckman Coulter Biomek i7 Hybrid Workstation

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Get Control in GMP Environments

- Getting Started with Kaluza: Data Scaling and Compensation Adjustment

- Getting Started with Kaluza: Parameters

- g-Max: Added Capabilities to Beckman Coulter's versatile Ultracentrifuge Line

- A method of grading nanoparticles using ultracentrifugation in order to determine the accurate particle diameter

- HIAC Industrial – Our overview solution for fluid power testing for all applications

- High throughput cultivation of the cellulolytic fungus Trichoderma reesei in the BioLector®

- High-Throughput qPCR and RT-qPCR Workflows Enabled by Echo Acoustic Liquid Handling and NEB Luna Reagents

- A Highly Consistent BCA Assay on Biomek i-Series

- A Highly Consistent Lowry Method on Biomek i-Series

- Highly Reproducible Automated Proteomics Sample Preparation on Biomek i-Series

- High-throughput IgG quantitation platform for clone screening during drug discovery and development

- High-throughput Miniaturization of Cytochrome P450 Time-dependent Inhibition Screening Using the Echo 525 Liquid Handler

- Cell Line Development – Hit Picking

- Host Cell Residual DNA Testing in Reduced Volume qPCR Reactions Using Acoustic Liquid Handling

- How Violet Side Scatter Enables Nanoparticle Detection

- Automating the Cell Line Development Workflow

- ICH Q2 – the Challenge of Measuring Total Organic Carbon in Modern Pharmaceutical Water Systems

- ICH Q2 – The Challenge of Measuring Total Organic Carbon in Modern Pharmaceutical Water Systems

- ICH Q2 – the Challenge of Measuring Total Organic Carbon in Modern Pharmaceutical Water Systems

- Illumina Nextera Flex for Enrichment on the Biomek i7 Hybrid Genomics Workstation

- Importance of TOC measurement in WFI in light of European Pharmacopoeia change

- Improved data quality of plate-based IgG quantification using Spark®’s enhanced optics

- Increased throughput for IgG quantification using Valita Titer 384-well plates

- Integration of the Vi-CELL BLU Cell Viability Analyzer into the Sartorius Ambr® 250 High Throughput for automated determination of cell concentration and viability

- Temperature dependence of hydrodynamic radius of an intrinsically disordered protein measured in the Optima AUC analytical ultracentrifuge.

- Introducing the Cydem VT Automated Cell Culture System: A high-throughput platform for fast and reliable clone screening experiments

- Issues with Testing Jet Fuels for Contamination

- Jurkat Cell Analyses Using the Vi-CELL BLU Cell Viability Analyzer

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Linearity of BSA Using Absorbance & Interference Optics

- LS 13 320 XR: Sample Preparation - How to measure success

- Beckman’s LS 13 320 XR Vs. Malvern Mastersizer

- Using Machine Learning Algorithms to Provide Deep Insights into Cellular Subset Composition

- Matching Cell Counts between Vi–CELL XR and Vi–CELL BLU

- Media optimization in the RoboLector platform for enhanced protein production using C. glutamicum

- MET ONE 3400+ LDAP & Active Directory connection Guide

- Method for Determining Cell Type Parameter Adjustment to Match Legacy Vi CELL XR

- Migration of Panels Designed on the CytoFLEX S Flow Cytometer to CytoFLEX SRT Cell Sorter

- Miniaturization of an Epigenetic AlphaLISA Assay with the Echo Liquid Handler and the BMG LABTECH PHERAstar FS

- Miniaturization of Cytochrome P450 Time-dependent Inhibition Screening Using the Echo 555 Liquid Handler

- Miniaturization and Rapid Processing of TXTL Reactions Using Acoustic Liquid Handling

- Miniaturized Enzo Life Sciences HDAC1 Fluor de Lys Assays Using an Echo Liquid Handler Integrated in an Access Laboratory Workstation

- Miniaturized Enzymatic Assays with Glycerol

- Miniaturized EPIgeneous HTRF Assays Using the Echo Liquid Handler

- Miniaturized Gene Expression in as Little as 250 nL

- Miniaturized Genotyping Reactions Using the Echo Liquid Handler

- Miniaturized Multi-Piece DNA Assembly Using the Echo 525 Liquid Handler

- Miniaturized Sequencing Workflows for Microbiome and Metagenomic Studies

- Minimizing process variability in the manufacturing of bottled drinking water

- Mixed Mode Sorting on the CytoFLEX SRT

- Mode of operation of optical sensors for dissolved oxygen and pH value

- Modular DNA Assembly of PIK3CA Using Acoustic Liquid Transfer in Nanoliter Volumes

- Multi-Wavelength Analytical Ultracentrifugation of Human Serum Albumin complexed with Porphyrin

- Nanoliter Scale DNA Assembly Utilizing the NEBuilder HiFi Cloning Kit with the Echo 525 Liquid Handler

- Nanoscale Sorting with the CytoFLEX SRT Cell Sorter

- What to do now that ACFTD is discontinued

- Low-pH profiling in µL-scale to optimize protein production in H. polymorpha using the BioLector

- Optimized NGS Library Preparation with Acoustic Liquid Handling

- Optimizing Workflow Efficiency of Cleanroom Routine Environmental Monitoring

- Spectral Flow Cytometry: A Detailed Scientific Overview

- Particle Counting in Mining Applications

- Performance of the Valita Aggregation Pure assay vs HPLC-SEC

- Phototrophic cultivation of Chlorella vulgaris in the BioLector XT microbioreactor

- Plate Deposition Speed Comparison of Astrios and CytoFLEX SRT Cell Sorters

- Precision measurement of adipocyte size with Multisizer4e

- Principles of Continuous Flow Centrifugation

- Flow Cytometric Approach to Probiotic Cell Counting and Analysis

- Protocols for use of SuperNova v428 conjugated antibodies in a variety of flow cytometry applications

- Purifying High Quality Exosomes using Ultracentrifugation

- Purifying viral vector with VTi 90 rotor and CsCl DGUC

- USP System Suitability

- Calibrating the QbD1200+ TOC Analyzer

- Quality Control of Anti-Blocking Powder Particle Size

- Quality Control Electronic Records for 21 CFR part 11 Compliance

- A Rapid Flow Cytometry Data Analysis Workflow Using Machine Learning- Assisted Analysis to Facilitate Identifying Treatment- Induced Changes

- Rapid Measurement of IgG Using Fluorescence Polarization

- Rapid Rabbit IgG Quantification using the Valita Titer Assay

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Root Cause Investigations for Pharmaceutical Water Systems

- Screening yeast extract to improve biomass production in acetic acid bacteria starter culture

- Single Cell Sorting with CytoFLEX SRT Cell Sorter

- Full Automation of the SISCAPA® Workflow using a Biomek NXP Laboratory Automation Workstation

- Leveraging the Vi-CELL MetaFLEX for Monitoring Cell Metabolic Activity

- Unveiling the Hidden Signals: Overcoming Autofluorescence in Spectral Flow Cytometry Analysis

- Sorting Rare E-SLAM Hematopoietic Stem Cells Using CytoFLEX SRT and Subsequent Culture

- Unlocking Insights: The Vital Role of Unmixing Algorithms in Spectral Flow Cytometry

- Specification Comparison of Vi–CELL XR and Vi–CELL BLU

- Specifying Non-Viable Particle Monitoring for Aseptic Processing

- A Standardized, Automated Approach For Exosome Isolation And Characterization Using Beckman Coulter Instrumentation

- Streamlined Synthetic Biology with Acoustic Liquid Handling

- Switching from Oil Testing to Water and back using the HIAC 8011+ and HIAC PODS+

- SWOFF The unrecognized yet indispensable sibling of FMO

- Advanced analysis of human T cell subsets on the CytoFLEX flow cytometer using a 13 color tube-based DURAClone dry reagent

- The scattered light signal: Calibration of biomass

- Comparative Performance Analysis of CHO and HEK Cells Using Vi-CELL BLU Analyzer and Roche Cedex® HiRes Analyzer

- Using k-Factor to Compare Rotor Efficiency

- Utilization of the MicroClime Environmental Lid to Reduce Edge Effects in a Cell-based Proliferation Assay

- Validation of On-line Total Organic Carbon Analysers for Release Testing Using ICH Q2

- Vaporized Hydrogen Peroxide Decontamination of Vi–CELL BLU Instrument

- Vertical Rotor Case Study with Adenovirus

- Vesicle Flow Cytometry with the CytoFLEX

- Automating the Valita Aggregation Pure Assay on a Biomek i-Series Liquid Handler

- Automating the Valita Titer IgG Quantification Assay on a Biomek i-Series Liquid Handling System

- Rapid, Automated Purification of Adeno-Associated Virus using the OptiMATE Gradient Maker

- Reducing Variability and Hands-On time in Viral Vector purification using the OptiMATE Gradient Maker

- Variability Analysis of the Vi-CELL BLU Cell Viability Analyzer against 3 Automated Cell Counting Devices and the Manual Method

- Vi-CELL BLU FAST Mode Option

- Vi-CELL BLU Regulatory Compliance - 21 CFR Part 11

- Viral Vector Purification with Ultracentrifugation

- Analytical Ultracentrifugation (AUC) for Characterization of Lipid Nanoparticles (LNPs): A Comprehensive Review

- Leveraging Analytical Ultracentrifugation for Comprehensive Characterization of Lipid Nanoparticles in Drug Delivery Systems

- Whole Genome Sequencing of Microbial Communities for Scaling Microbiome and Metagenomic Studies Using the Echo 525 Liquid Handler and CosmosID

- Catalogs

- Experimental Protocols

-

Brochures, Flyers and Data Sheets

- Access Single Robot System for Synthetic Biology Workflows

- Automated Solutions for Cell Line Development

- Automated Solutions for ELISA

- Echo Acoustic Liquid Handling for Synthetic Biology

- HIAC 8011+ Liquid Particle Counting Systems

- HIAC 9703+ Sub-Visible Particulate Testing

- LS 13 320 XR - Laser Diffraction Particle Size Analyzer

- Download the Valita Titer Assay Brochure

-

Case Studies

- Achieving Increased Efficiency and Accuracy in Clinical Testing

- Adenoviral Vectors Preparation

- Algae Biofuel Production

- Antibody and Media Development

- Autophagy

- B Cell Research

- Basic Research on Reproductive Biology

- Cardiovascular Disease Research

- Cell Marker Analysis

- Choosing a Tabletop Centrifuge

- Collagen Disease Treatment

- Controlling Immune Response

- Creating Therapeutic Agents

- DNA Extraction from FFPE Tissue

- English Safety Seminar

- Equipment Management

- Exosome Purification Separation

- Fast, Cost-Effective and High-Throughput Solutions for DNA Assembly

- Future of Fishing Immune Research

- Hematopoietic Tumor Cells

- High-throughput next-generation DNA sequencing of SARS-CoV-2 enabled by the Echo 525 Liquid Handler

- Hiroshima Genbaku HP Hematopoietic Tumor Testing

- iPS Cell Research

- Leveraging acoustic and tip-based liquid handling to increase throughput of SARS-CoV-2 genome sequencing

- Measuring the number of CD34 using AQUIOS

- Membrane Protein Purification X Ray Crystallography

- Organelles Simple Fractionation

- Particle Interaction

- Quality evaluation of gene therapy vector

- Retinal Cell Regeneration

- Sedimentary Geology

- Severe Liver Disease Treatment

- Tierra Biosciences reveals major molecular discovery

- Treating Cirrhosis

- University Equipment Management

- Fundamentals of Ultracentrifugal Virus Purification

- Flyers

-

Interviews

- Background and Current Status of the Introduction of Flow Cytometers

- Bacteriological-measurements-of-soil-bacteria-in-paddy-fields

- Benefits-of-the-coulter-principle-in-the-manufacturing-for-ips-cell-derived-natural-killer-cells

- Central Diagnosis in the Treatment of Childhood Leukemia 1

- Central Diagnosis in the Treatment of Childhood Leukemia 2

- Challenges-in-viability-cell-counting

- Contribution of Cytobank to 1-cell analysis of the cancer microenvironment

- Development of technology for social implementation of synthetic biology

- Flow Cytometry Testing in Hospital Laboratories

- Fundamentals of Ultracentrifugal Virus Purification

- Tumor Suppressor Gene p53 research and DNA Cleanup Process

- Fundamentals of Ultracentrifugal Virus Purification

- Dr Yabui UCF Lecture

-

Posters

- Applications of Ultracentrifugation in Purification and Characterization of Biomolecules

- Automating Genomic DNA Extraction from Whole Blood and Serum with GenFind V3 on the Biomek i7 Hybrid Genomic Workstation

- ABRF 2019: Automated Genomic DNA Extraction from Large Volume Whole Blood

- Automated library preparation for the MCI Advantage Cancer Panel at Miami Cancer Institute utilizing the Beckman Coulter Biomek i5 Span-8 NGS Workstation

- Automating Cell Line Development for Biologics

- Cell-Line Engeneering

- Characterizing the Light-Scatter Sensitivity of the CytoFLEX Flow Cytometer

- AACR 2019: Isolation and Separation of DNA and RNA from a Single Tissue or Cell Culture Sample

- Mastering Cell Counting

- Preparing a CytoFLEX for Nanoscale Flow Cytometry

- A Prototype CytoFLEX for High-Sensitivity, Multiparametric Nanoparticle Analysis

- ABRF 2019: Simultaneous DNA and RNA Extraction from Formalin-Fixed Paraffin Embedded (FFPE) Tissue

- Quantification of AAV Capsid Loading Fractions: A Comparative Study

- Using Standardized Dry Antibody Panels for Flow Cytometry in Response to SARS-CoV2 Infection

- Product Instructions

-

Whitepapers

- Centrifugation is a complete workflow solution for protein purification and protein aggregation quantification

- AUC Insights - Analysis of Protein-Protein-Interactions by Analytical Ultracentrifugation

- A General Guide to Lipid Nanoparticles

- Analytical Ultracentrifugation: A Versatile and Valuable Technique for Macromolecular Characterization

- Addressing issues in purification and QC of Viral Vectors

- GMP Cleanrooms Classification and Routine Environmental Monitoring

- Purification of Biomolecules by DGUC

- AUC Insights - Assessing the quality of adeno-associated virus gene therapy vectors by sedimentation velocity analysis

- AUC Insights - Sample concentration in the Analytical Ultracentrifuge AUC and the relevance of AUC data for the mass of complexes, aggregation content and association constants

- Analyzing Biological Systems with Flow Cytometry

- Changes to USP <1788> Subvisible Particulate Matter

- Changes to USP <643> Total Organic Carbon

- Characterization of RNAdvance Viral XP RNA Extraction Kit using AccuPlex™ SARS–CoV–2 Reference Material Kit

- CytoFLEX Platform Gain Independent Compensation Enables New Workflows

- CytoFLEX Platform Flow Cytometers with IR Laser Configurations: Considerations for Red Emitting Dyes

- Evaluation of the Analytical Performance of the AQUIOS CL Flow Cytometer in a Multi-Center Study

- Simultaneous Isolation and Parallel Analysis of gDNA and total RNA for Gene Therapy

- Hydraulic Particle Counter Sample Preparation

- Inactivation of COVID–19 Disease Virus SARS–CoV–2 with Beckman Coulter Viral RNA Extraction Lysis Buffers

- Tips for Cell Sorting

- Liquid Biopsy Cancer Biomarkers – Current Status, Future Directions

- MET ONE 3400+ IT Implementation Guide

- Reproducibility in Flow Cytometry

- SuperNova v428: New Bright Polymer Dye for Flow Cytometry

- SuperNova v428: New Bright Polymer Dye for Flow Cytometry

- Japan Document

-

Application Notes