Calculating k Factor

Most researchers refer to the maximum speed of a rotor to compare efficiency. This can be misleading as factors such as tube geometry and temperature contribute to rotor performance and must also be considered.

Separation is affected by maximum speed and radius which together determine maximum g-force. However, particle pathlength also affects separation time. A simple measure of overall rotor efficiency incorporating both g-force and particle pathlength is the k Factor. Generally, the lower the k Factor, the shorter the run time. This makes the k Factor one of the most important considerations when selecting a rotor.

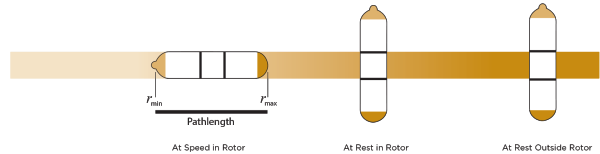

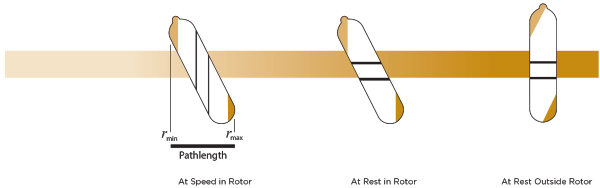

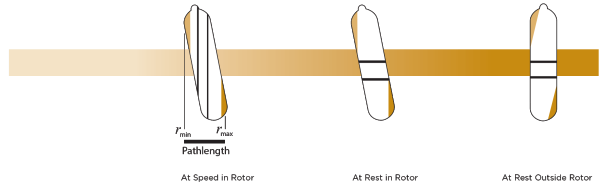

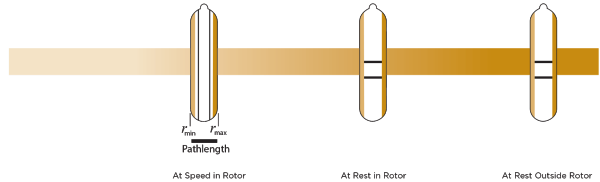

Particle Separation in Swinging Bucket, Fixed Angle, Near Vertical and Vertical Tube Rotors

Darker shading represents pelleted material. Lighter shading depicts floating components. Bands indicated by black lines.

Swinging Bucket RotorsTypical Example: SW 60 Ti Pathlength: 57.2 mm k Factor: 45 |

|

Fixed Angle RotorsTypical Example: 90 Ti Pathlength: 42.3 mm k Factor: 25 |

|

Near Vertical Tube RotorsTypical Example: NVT 90 Pathlength: 18.7 mm k Factor: 10 |

|

Vertical Tube RotorsTypical Example: VTi 90 Pathlength: 13.2 mm k Factor: 6 |

|