BioLector XT Microbioreactor

Microfluidic Bioprocess Control

Cultivation conditions

| 10 – 50 °C (min. temp.: 8 °C below ambient temp.) |

100 – 1500 rpm (3 mm diameter)

|

Active humidification

|

Ambient air

|

1 – 100 % O2 (optional)

|

0 – 12 % CO2 (optional)

|

Anaerobic cultivation (optional)

|

| 0 – 100 % dissolved oxygen*1 |

pH 4 – 7.5 (depending on plate)

|

2.7 min / filter / 48 wells @ 1000 rpm

|

Microfluidic features*2

pH control range: 4.0 – 7.5 (depending on plate)

|

| Fully editable PI control |

Slow, medium and fast PI default settings

|

Two sided pH control (alkali and acid)

|

One sided pH control and one feed line (alkali or acid + one feed)

|

Two feed lines

|

Profile equation: dV/dt =A+B×t+C×eD×t

|

Constant: A [μL/h]

|

Linear: A [μL/h] and B [μL/h²]

|

Exponential: A [μL/h], B [μL/h²], C [μL/h] and D [h-1]

|

Pulse feed

|

Full feeding profile flexibility permits broad experimental design

|

| Up to 665 pump strokes per hour |

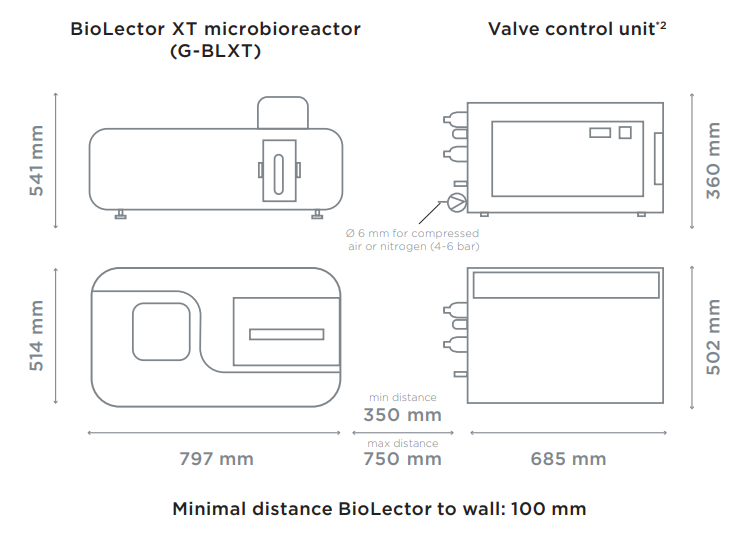

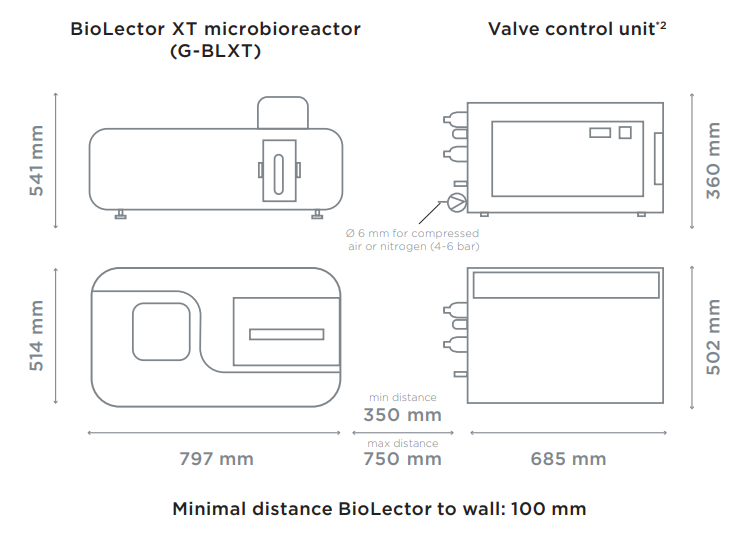

System dimensions

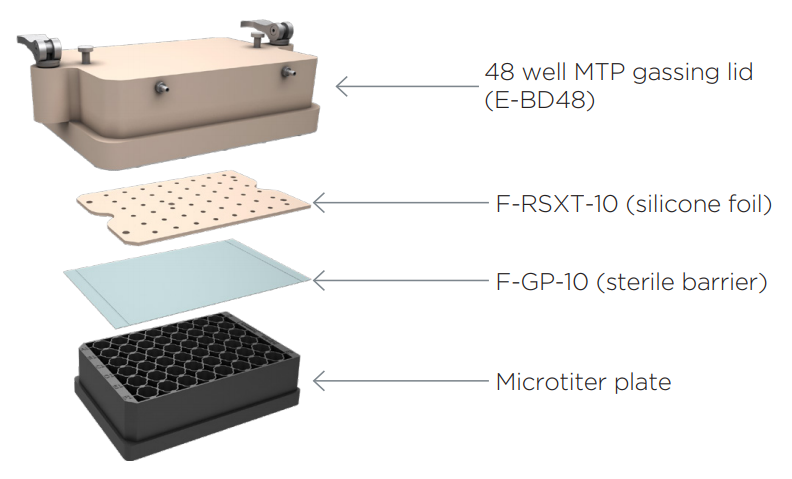

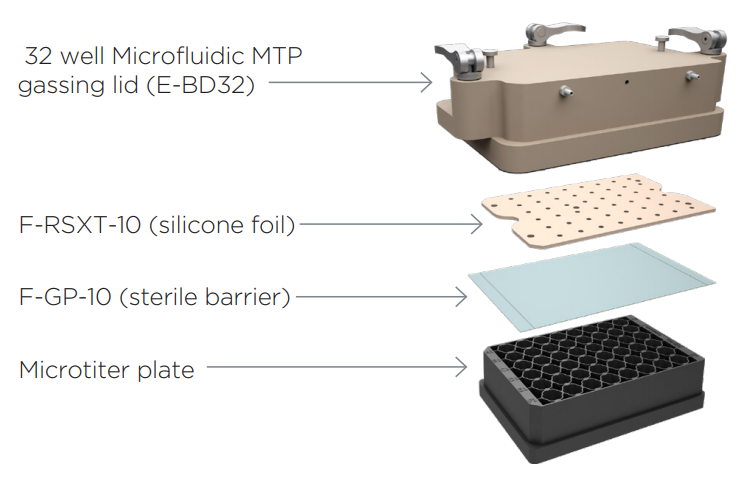

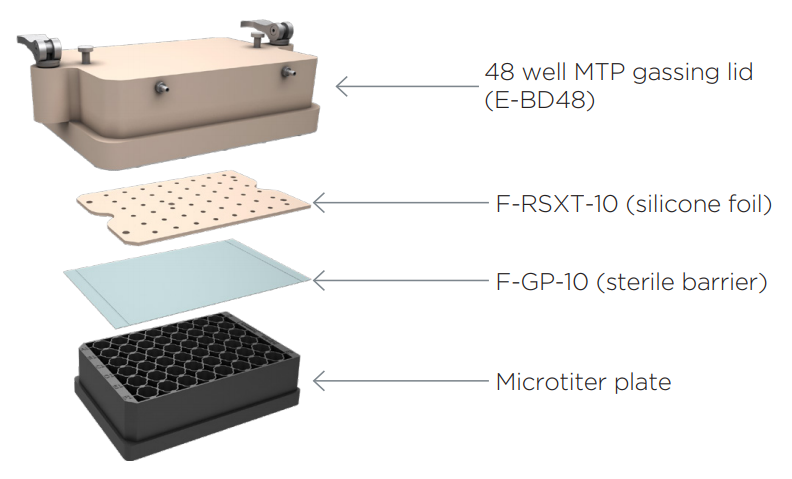

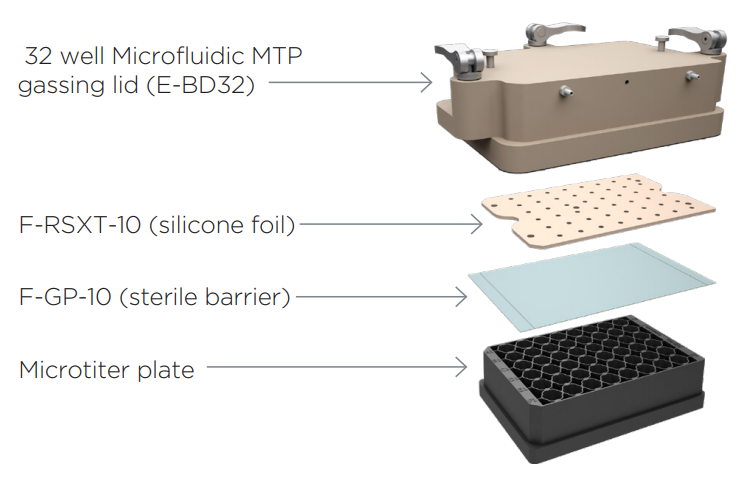

Gassing lid dimensions

Available optional modules

E-XTMF

|

TradeGothicLT-Extended

|

Active control of pH according to online signals and continuous feeding of up to two solutions |

only with Microfluidic plates

|

E-O2XT-100

|

O2 up-regulation module

|

Control of gas atmosphere in head space: 21 – 100 % O2

|

|

E-O2XT-25

|

O2 down-regulation module

|

Control of gas atmosphere in head space: 1 – 21 % O2

|

use only with N2

|

E-CO2XT-12

|

CO2 up-regulation module

|

Control of gas atmosphere in head space: 0 – 12 % CO2

|

|

E-AN-300

|

Anaerobic cultivation module

|

Gassing with 100 % N2 allows cultivation of organisms in anaerobic conditions

|

use only with N2

|

All optional modules compatible in one BioLector microbioreactor device.

|

Microtiter plates

48 cultivation wells

|

Filling volume: 800 – 1900 μL (rpm dependent)

|

High OTR and high kLa

|

48 cultivation wells

|

Filling volume: 1000 – 2400 μL (rpm dependent)

|

Lower OTR and low shear force

|

Available as both FlowerPlate and Round Well Plate

|

32 cultivation wells controlled by 16 reservoir wells

|

Maximum filling volumes in reservoir wells: 1800 µL (FlowerPlate) and 2000 µL (Round Well Plate)

|

Same filling volumes for cultivation wells as in 48 well plate

|

Lab space and material requirements

Flat surface with a minimal loading capacity of 100 kg for BioLector XT microbioreactor or 250 kg for BioLector XT microbioreactor with the valve control unit*2

|

Device weight: 58 kg for BioLector XT microbioreactor (61 kg with microfluidic module) and 44 kg for valve control unit*2

|

1x power supply for BioLector XT microbioreactor: 90-264 VAC, 47~63 Hz 1x power supply for laptop: 90-230 VAC, 50/60 Hz 1x power supply for valve control unit*2: 90-264 VAC, 47~63 Hz (US/Canada); 85-264 VAC, 47~63 Hz (EU, ROW)

|

Microfluidics: requires 4 to 6 bar dry and oil-free compressed air, 6 mm ØOUT push-in connection

|

Gassing modules (O2 up, O2 down, CO2 up, anaerobic module): require 1.5-2 bar dry and oil-free O2, CO2, or N2; 4 mm ØOUT push-in connection

|

Humidity control: 400 mL deionized water

|

*1 100 % corresponding to the DO level reached while gassing with 100 % O2 without O2 consumption

*2 only with optional microfluidic module OTR: Oxygen transfer rate [mmol/L/h]

kLa: Volumetric oxygen transfer coefficient [h-1]

m2p and the m2p logo are the trademarks or registered trademarks of m2p-labs GmbH in the US and other countries.

m2p-labs is a Beckman Coulter company.

Additional BioLector XT Content

Request more information about the Biolector XT