Applications of Ultracentrifugation in Purification and Characterization of Biomolecules

Content Type: Poster

Akash Bhattacharya,1 Ross VerHeul,2 Eric Von Seggern,1 Stephen Otts,2 Beckman Coulter, Inc., 1Loveland, CO & 2 Indianapolis, IN, USA

Introduction

Ultracentrifuges spin samples with centrifugal forces typically spanning 100,000 – 1,000,000 x g. At these high forces, the constituent molecules in the sample separate based on their physical properties (e.g., size, mass, density, anisotropy). Accordingly, ultracentrifugation is commonly used to purify, as well as characterize, low-molecular weight polymers up to multi-megaDalton protein complexes and organelles.

Preparative Ultracentrifugation

Differential Ultracentrifugation

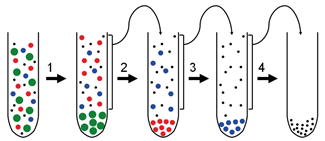

- Particles are separated on the basis of their size and mass (sedimentation coefficient, S).

- Multiple pelleting steps may be used for iterative enrichment.

- Ideal for separating particle groups of very different sizes.

Density Gradient Ultracentrifugation (DGUC)

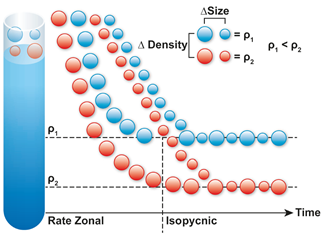

- Soluble particles are separated in a liquid column of varying density (density gradient)..

- In rate zonal experiments, particles migrate at varying rates, dictated by their S-values, and are time-dependent.

- Isopycnic separations are time-insensitive, where particles migrate to their apparent buoyant density in the gradient.

- Ideal for high-resolution separation of small materials with similar physical properties.

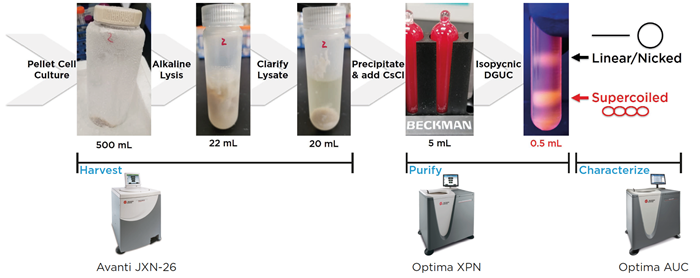

Example Workflow for DGUC Purification of Plasmid DNA

- Plasmid DNA may be extracted from bacteria using a variety of methods..

- The workflow below depicts a common alkaline lysis extraction and purification via a cesium chloride (CsCl) density gradient method with ethidium bromide.

- Newer density gradient materials (i.e., iodixanol/OptiPrep) and DNA-interacting probes (e.g., DAPI & GelGreen) may also be used in plasmid purification.

AUC History

|

Theodor Svedberg invents AUC, Chemistry Nobel Prize 1926 |

|

|

Jean Perrin describes Sedimentation Equilibrium, Physics Nobel Prize 1926 |

|

|

Ole Lamn describes the sedimentation and diffusion of samples in a sector-cell, 1930s |

|

|

Edward Pickel starts Spinco and builds the first commercial AUC - the model E, 1947 |

|

|

Beckman acquires Spinco, 1954 |

|

|

Meselson & Stahi experiment, 1954 |

|

|

Schachman develops Rayleigh interface detection, 1958 |

|

|

Van-Hoide Weischet graphical analysis is developed, 1978 |

|

|

Beckman introduces the Proteomelab XLA/XLI AUC instrument, 1990s |

|

Demeler develops Ultrascan, 1998, Shuck develops Sedfit, 2000 |

|

Beckman releases the new generation Optima AUC with multi-wavelength capability |

|

New frontier: Viral vectors, nanoparticles, liposomes |

AUC Fundamentals

Components of an AUC Cell

- Two-sector centerpiece sandwiched between two quartz or sapphire windows & assembled into a cylindrical housing.

- A screw ring is torqued to seal the cell.

- A counterbalance is necessary.

AUC Rotor & Optics

- 4- and 8-hole rotors are rated to 60,000 and 50,000 rpm, respectively.

- Interference and multiwavelength optics can be used in tandem.

Introduction to Sedimentation Velocity Data

- Sample migation produces moving boundaries which contain sedimentation and diffusion information.

AUC WORKFLOW CASE STUDY WITH INSULIN

Comparison of ProteomeLab vs Optima AUC

QUALITY CONTROL & CHARACTERIZATION USING AUC

Quantification of Aggregation and Degradation of Biological Samples and Elucidation of Molecular Shape

References: (1) By Thomasione, Public Domain, commons.wikimedia.org/w/index.php?curid=37665969.

(2) Ultrascan: www.ultrascan3.aucsolutions.com. (3) Sedfit: www.analyticalultracentrifugation.com.

CENT-4959PST02.19