Liquid Handling for Genotyping

Lower Costs, Increase Throughput and Significantly Improve Data Quality

Echo Liquid Handlers use non-contact acoustic liquid transfer technology to enable miniaturization of genotyping assays in 384- and 1536-well format. The tip-less technology of the Echo makes it a perfect solution for genotyping in any mid- to high-throughput lab.

Common genotyping methods tend to be characterized by relatively slow throughput and data variability. Lowering the genotyping reaction volumes is a way used to reduce the reacion costs for the genotyping applications. Tip-less, touch-less and acoustic-based transfers with the Echo liquid handlers greatly simplifies assay development efforts and reduces costs for genotyping. Precise and accurate drop placement minimizes the chances of cross-contamination and makes it possible to transfer liquids from any well of a source plate to any well of a 96-, 384- or 1536-well destination plate.

Common genotyping methods tend to be characterized by relatively slow throughput and data variability. Lowering the genotyping reaction volumes is a way used to reduce the reacion costs for the genotyping applications. Tip-less, touch-less and acoustic-based transfers with the Echo liquid handlers greatly simplifies assay development efforts and reduces costs for genotyping. Precise and accurate drop placement minimizes the chances of cross-contamination and makes it possible to transfer liquids from any well of a source plate to any well of a 96-, 384- or 1536-well destination plate.

Key Benefits

- Significant cost savings over traditional and chip-based microfluidics approaches

- A great fit to any laboratory due to being compatible with any chemistry and detection techniques

- Significant reduction of assay development iterations with multiplexed PCR conditions

- Fast and low-volume reaction setups in sub-microliter volumes, while maintaining/improving data quality1

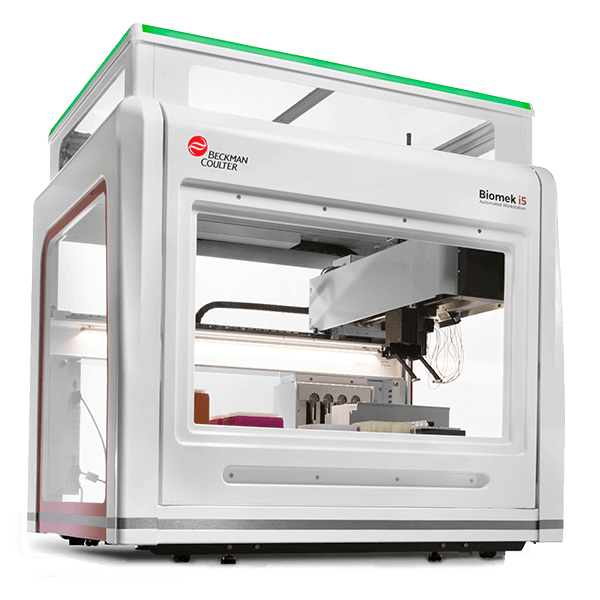

Access Systems for a High-Throughput and Walk-Away Solution

To expand these benefits even further, the Access Laboratory Workstation and Access Systems incorporate the Echo Liquid Handler into a turnkey, automated solution for high throughput genotyping studies.